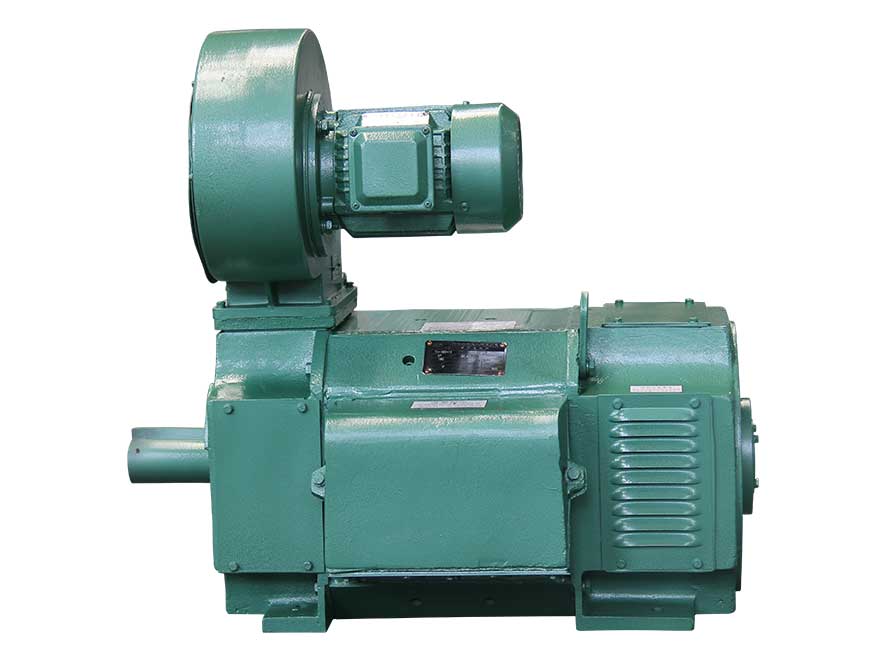

The main internal structure of the motor includes permanent magnet, rotor (coil), commutator brush, and commutator; After the motor is connected to direct current, the rotor coil becomes an electromagnet and rotates; As the rotor rotates, the current in the coil will change direction due to the action of the commutator, thereby changing the magnetic poles of the rotor (electromagnet), allowing the rotor to continue to rotate. In summary, an electric motor converts electrical energy from a power source into mechanical energy and outputs it through a shaft; There are two types of mechanical energy output: drive mode - the output rotation of the motor, which is converted into low-speed rotation through a gearbox or a series of other customer components. Translational motion; Vibration mode - providing vibration function by driving the pendulum to rotate.

What is the reason why DC permanent magnet motors produce noise? In fact, not all DC motors produce noise over time. Noise is generally caused by three reasons:

1. DC motor bearing sound: Generally, replacing the DC motor bearing can eliminate the problem. The bearing surface appears intact, but many factors can cause damage to the bearing: incorrect force point when pressing the bearing, tight fit between the shaft and the bearing, excessive bearing force when installed in the bearing chamber, or uneven radial bearing force caused by rotor balance.

2. In general, the main body of the carbon brush is not smooth enough, the running-in treatment is not good enough, and the commutator plate has suffered significant wear due to long-term operation. Over time during operation, problems such as overheating and loud noise can occur. Treatment method: Polish the main body to make it smooth enough, replace the commutator, and regularly supplement it with lubricating oil to slow down wear.

3. Friction sound between DC motor carbon brush and commutator: An experiment should be conducted in this regard. The precision turning of DC motor is a very important process, but the specific process parameters need to be explored.

Electricmotor

Electricmotor